Our Technology

World’s first climate positive continuous cellulose filament yarn

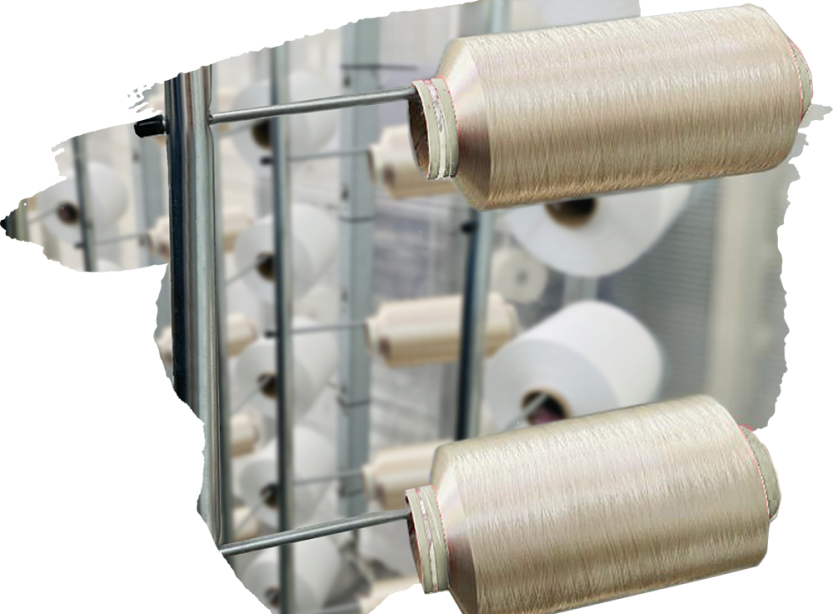

HeiQ AeoniQ™ is manufactured through an innovative proprietary process. Water is recycled more than 99% and the choice of raw materials prioritize those that help to decarbonize the atmosphere. HeiQ AeoniQ™ can be manufactured from different cellulosic raw materials which can be locally sourced depending on regional availability.

Our Technology

World’s first climate positive continuous cellulose filament yarn

HeiQ AeoniQ™ is manufactured through an innovative proprietary process. Water is recycled more than 99% and the choice of raw materials prioritize those that help to decarbonize the atmosphere. HeiQ AeoniQ™ can be manufactured from different cellulosic raw materials which can be locally sourced depending on regional availability.

Brand Story

Aeon: striving for eternal circularity

Enhancing the lives of billions through sustainable innovative and disruptive technologies has been HeiQ’s declared mission since its inception.

Clothing a potential 8 billion people is a daunting challenge.

Doing so with climate-positive textiles is even more challenging in a synthetic fiber dominated industry. Going beyond sustainability into the realms of circularity has always been the holy grail of textiles.

The development of HeiQ AeoniQ™ - the world’s first climate-positive cellulose yarn – is the ultimate example of HeiQ’s core philosophy of developing novel technologies to address significant global challenges. It also underlines the company’s potential to identify opportunities, develop relevant products, as well as manufacture and commercialize them.

Our mission is to make textiles sustainable and eternally circular, and protect our oceans by stopping microfiber pollution generated by synthetic fibers.

Factory

Path to Mass Production

A pilot plant with 100 tons per year capacity is operational since Q2, 2022. A Giga-Factory commercial asset is scheduled for 2025. HeiQ has called for early adoption commitments from key industry players and leading brands with the promise of exclusive lead time. After the completion of the first Giga-Factory with a partner (Joint Venture) in Europe, HeiQ will license its technology to ensure the worldwide production and cover the required capacities.

HeiQ AeoniQ™ Strengths

Uncompromising Performance

- Can be texturized

- Spin dyed (dope dyed)

- Shaped to functional cross sections

- Utilized in standard textile processes

- Yarn count: 50-1000 dtex

- Filament count: 1.5-6 dtex

- Tenacity: 25 to 45 cN/tex

- High elongation: 12 to 18%

- Low shrinkage: < 3%

- Matches Polyester & Nylon: quick dry & stretchable

- Matches Viscose: smooth & cool

- Matches Cotton: full & cozy

And for Weavers, Knitters and Dyers it is 'Business as Usual'

Use existing equipment

Use standard dyes

Use standard prints

Use existing functional finishes

Use combinations with other fibers

People Who Make It Possible

Julien Born

CEO

HeiQ AeoniQ Holding AG

Carlo Centoze

Co-Founder HeiQ & Group CEO

Board of Directors

HeiQ AeoniQ Holding AG

Carmen Danner

Director Business Development

HeiQ AeoniQ Holding AG

Martin Gebert-Germ

Technical Consultant Fiber & Product

HeiQ AeoniQ Holding AG

Enrique Herrero Acero

CTO

HeiQ AeoniQ Holding AG

Dominic Renggli

HeiQ AeoniQ Holding AG

Nelson Canoeiro Fernandes

Operations Director – Portugal

HeiQ AeoniQ Holding AG

Frequently Asked Questions

HeiQ’s first pilot production plant in Herzogenburg, near Vienna (Austria), is set up and running since Q2/22. The capacity of filament production is always depending on the yarn count. The first machine will produce ca. 100t/year on the max yarn count. More machines will be added soon.

HeiQ AeoniQ™ aims to replace polyester and nylon. Every ton of polyester causes 4 tons of CO2 emission. Cellulose is a biopolymer that binds CO2 from the atmosphere during its growth. It acts as a sink and various sources of cellulose have different sink potential. By replacing polyester and using for example non valorized agricultural cellulosic waste, 5 tons of CO2 emission are prevented.

If compared to the HIGG Index, HeiQ AeoniQ™ has the potential for the lowest ever environmental footprint for fibers. An LCA, also validated by a third party, is in place.

HeiQ is seeking to associate with 20 partners on the brand and operational side (mill partners). Any partnership on the brand side must be seen as a first commercial adoption, which will drive product shipments to the mills and markets.

HeiQ is eager to team up with globally selected mills bringing a strategic advantage to facilitate the supply chain and securing a fast scale-up of the technology. See Business Partner opportunities in the Become a Business Partner area of this website.

The first fabrics have been made with yarn from our pilot plant and designated R&D partners in Europe (Italy and Portugal) in knits and wovens. The fabrics have shown the desired performance parameters and we will be able to supply sufficient yarn for the development of capsule collections and salesman samples as of Q4/2022.